Product Center

JT-ⅡTBH enhanced special series grinding aid

Mainly applicable to ordinary Portland cement produced with the admixture of dihydrate gypsum or blended gypsum, especially composite silicate cement based on limestone or fly ash. When the moisture content of the raw materials is not more than 2.0%, the use of this grinding aid can improve the mill output and reduce the clinker consumption. When the fineness of cement 45μm sieve residue remains unchanged, the mill output can be increased by about 10%. While maintaining the basic cement ratio unchanged, the 3-day compressive strength of cement can be increased by 1-3 MPa, and the 28-day compressive strength can be increased by 3-4 MPa. When the cement strength and mill output remain basically unchanged, clinker can be reduced by 6%-8%, replaced by an equal amount of supplementary cementitious materials. The setting time of cement can be extended by 2-4 hours.

Cement grinding aid

Details

I. Product Characteristics

The product is a liquid, available in three packaging options: 1-ton bags, 250kg drums, and bulk packaging.

Density: 1.25-1.30 (g/cm3) (20℃)

PH: 8.70-9.30 (20℃)

Solid content: 45-55 (%)

Suitable dosage: 0.1-0.15 (%)

II. Scope of Application and Usage Effects

Mainly suitable for ordinary silicate cement produced using dihydrate gypsum or mixed gypsum, especially for composite silicate cement primarily using limestone or fly ash.

When using this grinding aid with raw material moisture content not exceeding 2.0%, it can increase the mill output per unit time and reduce the clinker consumption.

When the fineness of the cement leaving the mill (45μm residue) remains unchanged, the mill output per unit time can be increased by about 10%.

While maintaining the basic cement ratio unchanged, the 3-day compressive strength of the cement can be increased by 1-3 MPa, and the 28-day compressive strength by 3-4 MPa.

When the cement strength and mill output per unit time remain basically unchanged, 6%-8% of the clinker can be reduced and replaced with an equal amount of supplementary cementitious materials.

It can extend the setting time of cement by 2-4 hours.

III. Usage Examples

(Henan Cement Plant Ø3.2m×13m open-circuit mill)

|

P·C32.5 |

Mixed Materials and Dosage (%) |

Grinding Aid (%) |

Output per Unit Time |

45µm |

Initial Setting (h) |

Final Setting (h) |

Cement Compressive Strength (MPa) |

||||

|

Clinker |

Gypsum |

Limestone |

Fly Ash |

3 Days |

28 Days |

||||||

|

Blank Sample |

56 |

5 |

15 |

24 |

00 |

70 |

7.8 |

4:23 |

5:25 |

16.2 |

36.5 |

|

Test Sample |

50 |

5 |

18 |

27 |

0.12 |

73 |

7.5 |

6:15 |

7:20 |

16.3 |

37.6 |

IV. Characteristics of Cement Using This Grinding Aid

1. The fluidity of the cement powder will increase.

2. The flow of cement mortar will slightly increase.

3. The water requirement for standard consistency will slightly decrease.

4. The setting time will slightly extend by about 2-4 hours.

5. It is recommended to control the fineness of the cement leaving the mill using a 45μm sieve; the residue will decrease, but the specific surface area may not necessarily increase.

V. Addition Method During Use

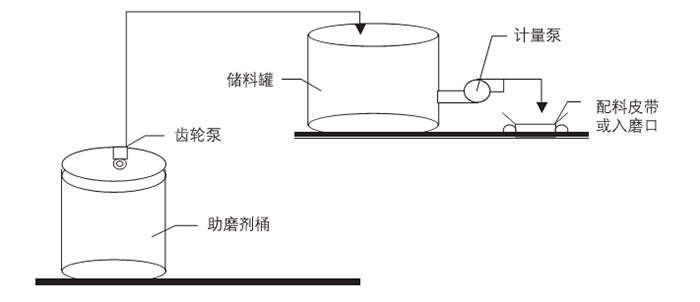

When a higher feeding height is required, a two-stage pumping method is generally used, as shown in the diagram below:

When no height increase is needed, a metering pump can be used directly for metering and addition.

Our company provides information on manufacturers of relevant metering devices.

Detection and control method of feeding amount: Based on the mill output and the amount of grinding aid added, calculate the mass (g) of grinding aid that should be added per minute. Use a 250-1000ml measuring cylinder to randomly collect the material from the pipe injecting the grinding aid into the mill for 1 minute, and weigh the collected grinding aid. When the feeding amount is inconsistent with the calculated amount, slightly adjust the speed of the metering pump until the specified requirements are met.

VI. Precautions

1. This grinding aid should be used after passing inspection. The acceptance inspection method is: Using a cement without any additives, conduct tests on both a sample of the grinding aid with confirmed quality and a sample of newly arrived grinding aid. Prepare cement samples with the appropriate dosage of each. Compare the 3-day and 28-day strengths of the two cement samples. If the strength of the cement sample with the newly arrived grinding aid is not lower than, or is basically the same as, that of the sample with the stored grinding aid, it is considered qualified.

2. During transportation and storage, prevent dropping, impact, external force compression, and proximity to high temperatures. The stacking height should not exceed two drums.

3. Before use, check the company's label before opening the seal, and confirm that the product and model are correct before use.

4. This product has mild corrosive properties to the skin. After skin contact, rinse with water; it must not be ingested.

5. When using this product, if the ambient temperature is continuously below 5℃ for 5 days, insulation measures should be taken to prevent product crystallization from affecting normal use.

6. The shelf life of this series of products is 6 months.